BEHIND ROLEX’S ICONIC WATCH FACES

Rolex’s in-house design team exemplifies the mastery of watch face design.

Dials in decorative stone: eisenkiesel (Day-Date 40), onyx (Day-Date 40) and turquoise (Day-Date 36

The dial plays an essential role in conveying the aesthetic identity of a watch. This is why Rolex performs its dial production in-house, mastering ancestral techniques and avant-garde technology. The product of several months of research and development, Rolex dials reflect the brand’s evolving style choices and illustrate its creative potential.

Each dial is a miniature work of art. The colour, reflections and surface texture, along with decorative elements and the overall design give the watch its intrinsic character. Made from a disc of brass, or sometimes precious metal (18 ct yellow, white or pink gold), Rolex dials are coloured using different techniques. They may also feature mother-of-pearl, natural stone or meteorite.

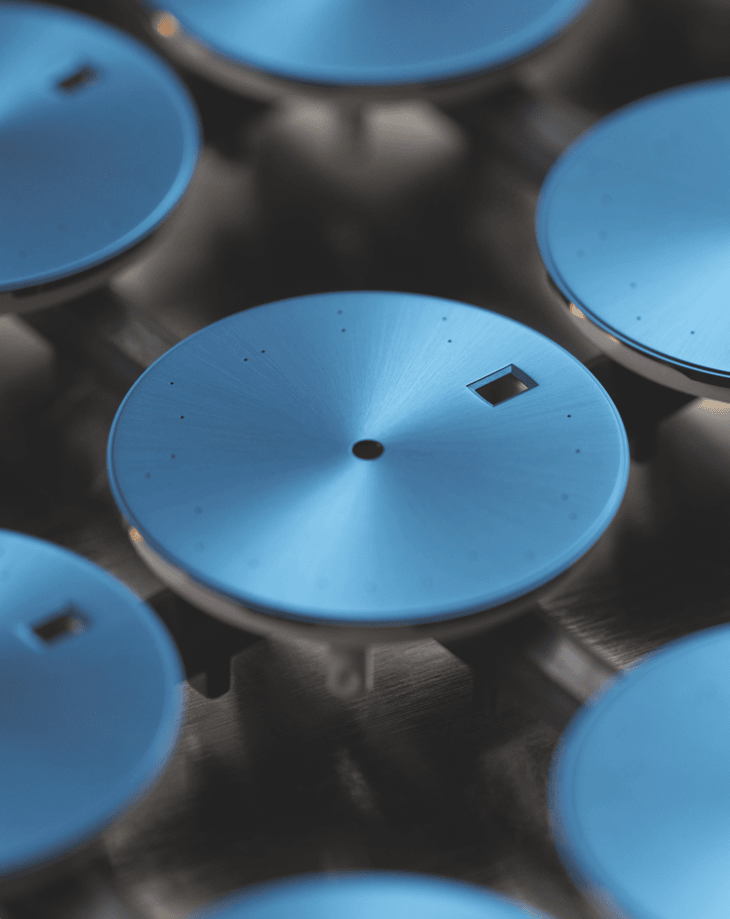

Dial with sunray finish after colouring via PVD (Physical Vapour Deposition)

Rolex masters its dial creation and production in- house. From the initial sketches to the final inspection, including colouring and the placing of appliques, the process involves a series of steps and operations that call on specific expertise. Some of these professions – enamelling, for instance – date from the early days of watchmaking, while others are inherent to the use of cutting-edge technologies. The manufacture of dials perfectly encapsulates the philosophy that guides the brand: seeking the highest level of quality to achieve an impeccable, long-lasting result.

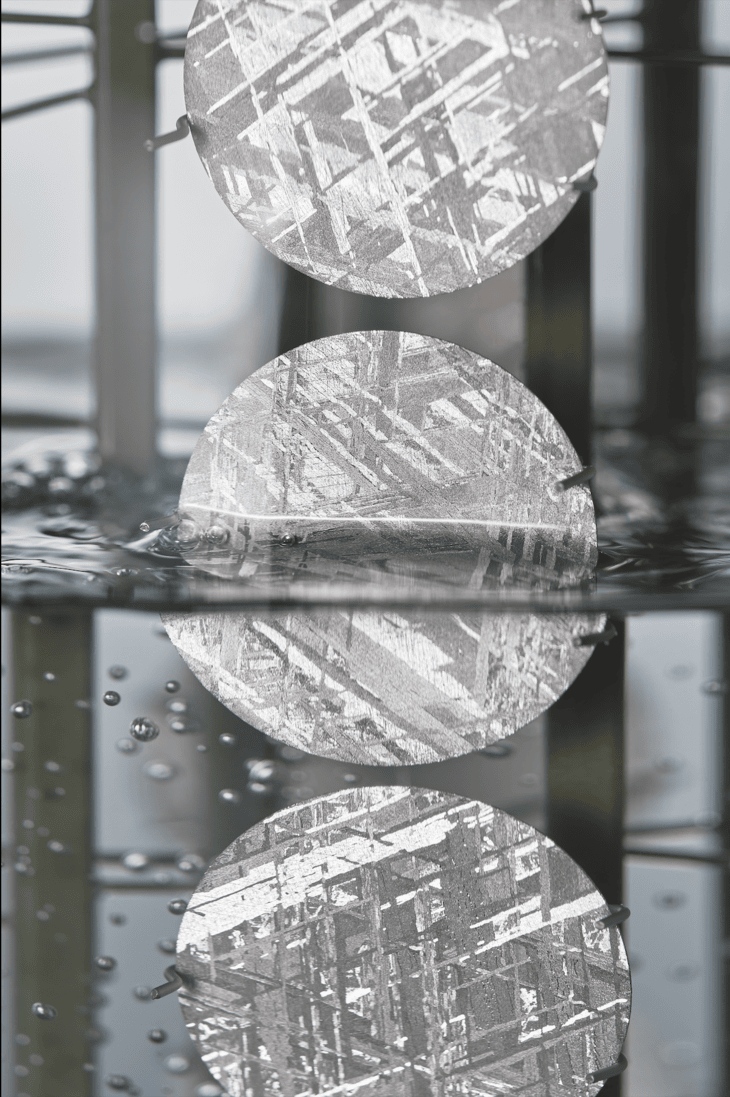

Meteorite dials during electroplating

THE THREE PRINCIPAL TECHNIQUES

Three different methods are used to colour the dials: lacquering, electroplating and PVD (Physical Vapour Deposition).

Lacquering is used to create deep or intense colours such as black and white, as well as pink, turquoise blue and green. Fine layers of lacquer are applied by airbrushing in a clean room, to eliminate dust particles. Once the lacquering is completed, the dial is covered with a coat of transparent varnish, which is then polished to a deep shine.

Testing for the right shade of lacquer according to the sketches created by the Design Department

Electroplating creates metallic colours. In this electrochemical process, the dials are coloured by immersing them in electrolytic baths; there, an electric current attracts metal ions suspended in the liquid and deposits them in thin layers on the dial. Silver, champagne-colour, slate and steel dials, for example, are obtained via this method, which can also be used to make black dials.

PVD techniques, of which there are several variants, consist in covering the dial’s brass base plate with ultrathin layers of oxides, metal alloys or nitrides. The equipment required for the PVD process is extremely complex and also highly sensitive. To avoid any dust contamination of the dial’s immaculate surface during the process, the engineers work in the strictly controlled atmosphere of a clean room and wear full protective suits at all times. This surface treatment allows luxurious tones to be produced such as olive green or chocolate, in addition to distinctive Rolex shades like bright blue, and softer, more muted nuances including pink, ice blue and dark grey.

Rolex dials that can made from natural materials, including green aventurine, mother-of-pearl, or diamond paved (Day-Date 36)

LET THE EYE BE THE JUDGE

The colours developed by Rolex are the outcome of extensive research and draw on a range of skills. Some hues are called on to vary in tune with fashions and tastes. In the 1980s and 1990s, the nuance of the classic Rolex champagne-colour evolved several times, gaining in warmth and pinkness before it retreated to greater subtlety. Ice blue, another distinctive Rolex shade, reserved for watches in 950 platinum, has also varied over the years.

Final surface finishing can alter the appearance and texture of the dials significantly. Even a simple black gains intensity with a matt varnish, while gloss varnish will give the same black a more refined and elegant look.

Ultimately, despite the advanced technology mobilized in its conception, the judgement and approval of the new tint for a dial will be eminently human. Laboratory apparatus may be able to measure the colour and characteristics of the thousands of shades already created at Rolex, but it lacks the ability to judge beauty. That appreciation comes only from the finesse of the naked eye.

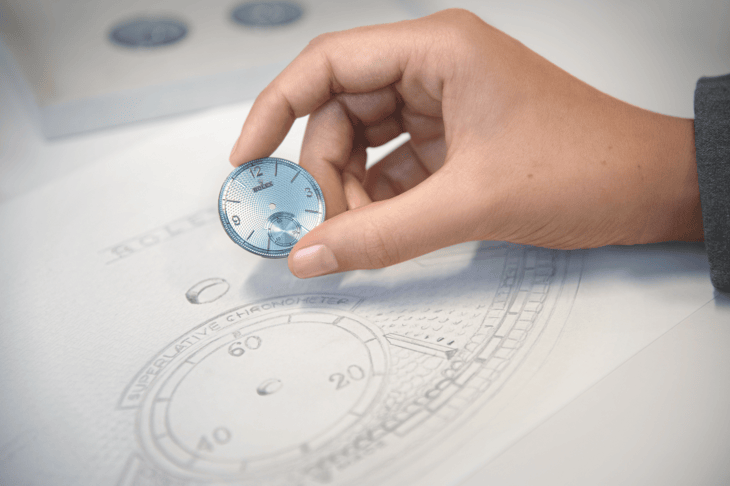

The dial of the Perpetual 1908 in 950 platinum with its sketch

DIALLING IN ON NATURE

Rolex has developed special expertise in the creation of dials made from natural stone – eisenkiesel, opal, green aventurine, carnelian or turquoise, for instance. Cut from a block of raw material, only the discs of material whose colour and structure fully satisfy the brand’s exacting aesthetic requirements are selected to eventually grace the dial of a Rolex watch, conferring it with a unique face and distinct personality.

Hand-setting an 18 ct Everose gold dial with diamonds

The brand also produces dials in natural mother-of-pearl, which can be white (South Asian) or black (Tahitian). White mother-of-pearl is found in two varieties. The most common has an iridescent and relatively uniform surface. The second, called ‘pearlized’ mother-of-pearl, presents an irregular, voluminous texture whose appearance evokes tiny overlapping clouds. This rarest and most prestigious variety of white mother-of-pearl is extracted from the heart of the pearl oyster shell – the oldest part – from which only one or two discs of material can be taken.

Bright black and steel dial with contrasting counters (Cosmograph Daytona) and black dial with large 3, 6 and 9 hour markers and a prominent minutes scale (Air-King)

Formed in the far reaches of the solar system, metallic meteorite, for its part, comes from an asteroid that exploded millions of years ago. On the voyage between planets, fragments of this natural extraterrestrial material, primarily composed of iron and nickel, cool by a few degrees Celsius every million years, creating unique, distinctive crystallization within the material that is impossible to recreate on Earth. Metallic meteorite is rare and challenging to work with, but once it is cut into thin sections and a chemical treatment is applied, the great beauty of its interwoven internal structure is revealed. These fascinating and varied formations are known as Widmanstätten patterns. For its dials, Rolex works with leading experts in the field and selects only the sections of meteorite with a particularly well-formed surface rich in different shapes and reflections.

Dial with motif made using the champlevé method of grand feu enamelling (Day-Date 36)

THE TRADITIONAL CRAFTSMANSHIP OF ENAMELLING

Rolex masters in-house the expert technique of grand feu enamelling. This complex métier d’art is used in watchmaking particularly for the decoration of dials. Grand feu enamel is reputed for the intensity of the many colours it can produce. The enamelled surfaces also remain perfectly stable over time, especially with regard to colour. The puzzle motif dials on the exclusive versions of the Oyster Perpetual Day-Date 36 presented in 2023 were created using grand feu enamelling. This traditional craft is also employed at Rolex to form the hour markers gracing certain diamond-paved dials.

More posts

La Dame De Pic

03 Dec 2020

Navigating Through Time

15 Nov 2020

Mercedes-AMG GLB 35 4MATIC

13 Nov 2020